Reduce, reuse, recycle: towards a circular organisation with the R-ladder

Recycling—who isn’t familiar with the term? If you’re already recycling, such as by separating your business waste, you’re on the right track! But did you know there are even more sustainable ways to use resources? Methods that help preserve the original value of materials as much as possible.

At Seenons, we believe that waste is simply resources in the wrong place. To use these resources as efficiently and sustainably as possible, you can apply the circular strategies of the R-ladder.

What exactly is the R-ladder, and how can you apply it to your organisation? We explain it all so you can get started on your journey to a world without waste!

In dit artikel:

What is the R-ladder?

Why is the R-ladder important to circularity and sustainability?

The Seenons R-ladder; Our Road to Circularity

Measurability: How do we make the R-ladder practical?

Download the R-ladder in PDF 📄

What is the R-ladder?

The R-ladder is a method to assess the level of circularity of a material or waste stream. The steps are ordered based on how much they contribute to preserving material value: the higher the step, the more value is retained and the less waste and energy loss occur. This makes it a practical tool for prioritizing actions to improve waste management sustainability.

Why is the R-ladder important for circularity and sustainability?

Resources are becoming increasingly scarce, while demand continues to rise. At the same time, we face the immense challenge of reducing CO₂ emissions to combat climate change. It’s time for action! The Netherlands and the European Union have set ambitious goals: achieving a fully circular economy by 2050 (source: Dutch government).

In a circular economy, waste no longer exists. Everything we use is either reused or processed into new products and materials. Waste becomes a resource, and that’s precisely what makes the R-ladder so important: it provides organisations with a clear roadmap to make this transition.

By applying the strategies of the R-ladder, you can:

- Save resources: Reduce waste and decrease dependency on scarce materials.

- Lower costs: Optimise material use to save on waste processing and procurement.

- Increase impact: Each step on the ladder helps reduce CO₂ emissions and contributes to a more sustainable world.

Whether you start small, like reducing paper usage, or take bigger steps by repairing and reusing products—every action counts. The R-ladder helps you make informed decisions that benefit both the environment and your organisation.

The Seenons R-ladder; Our Road to Circularity

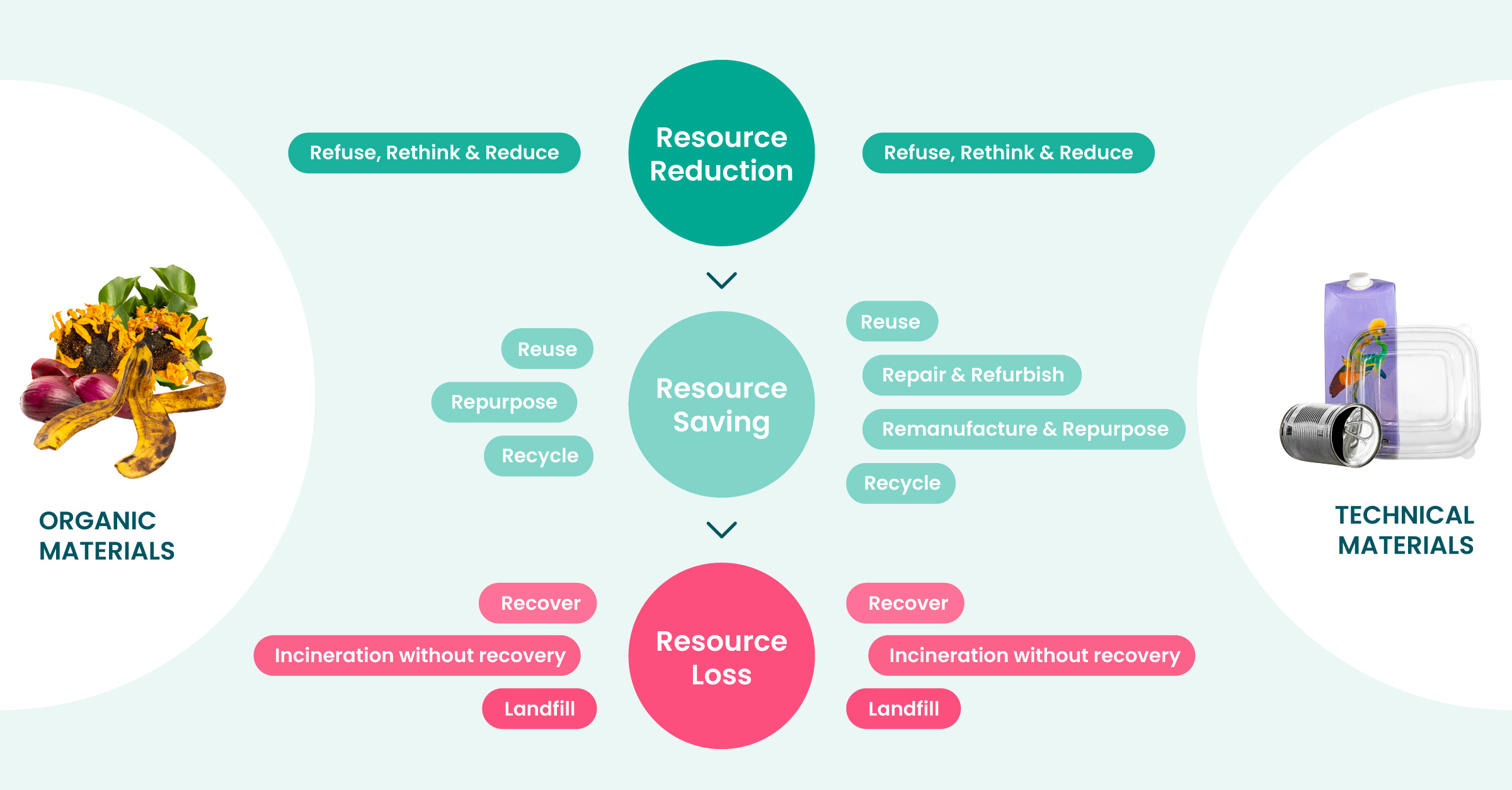

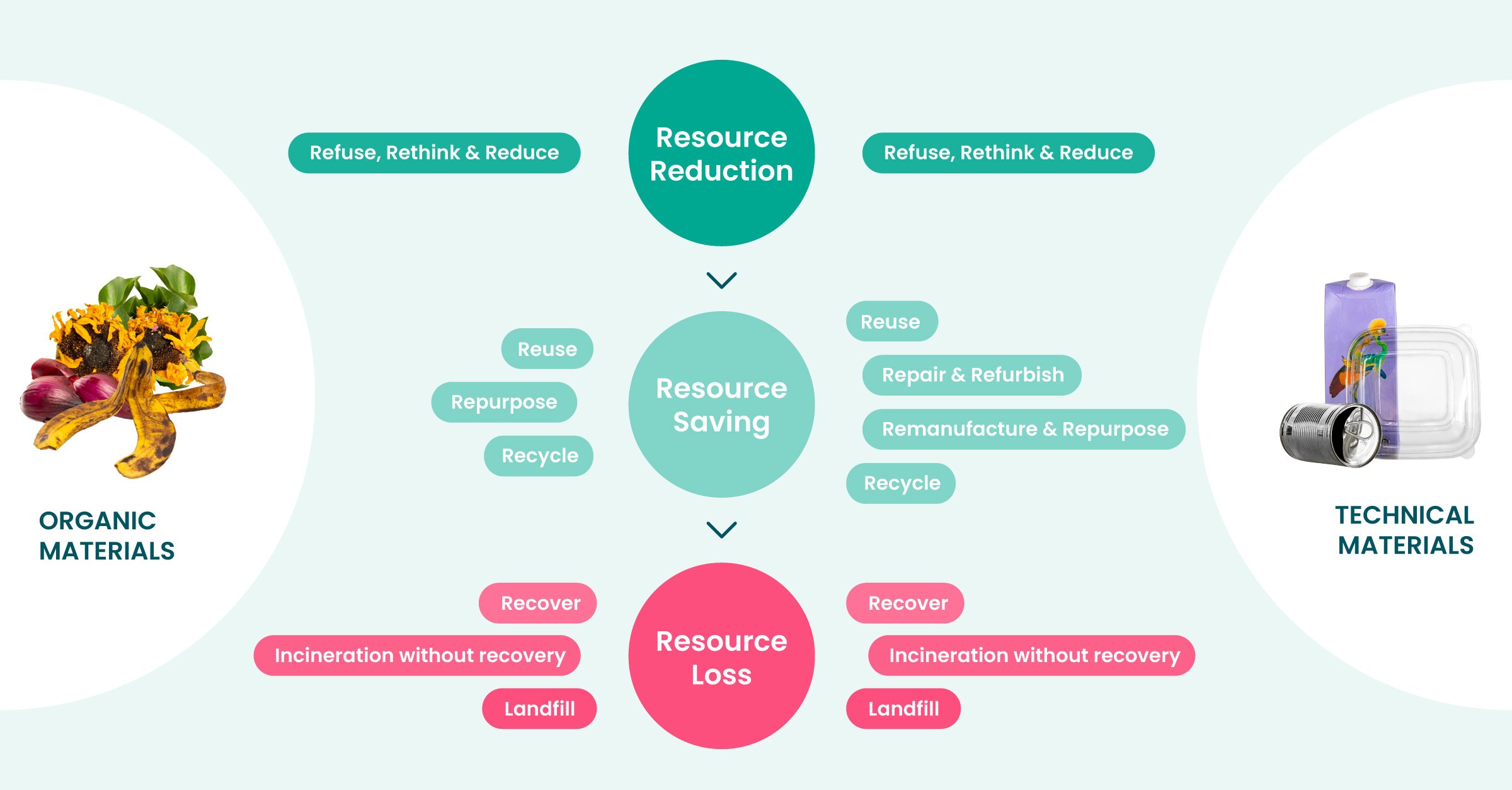

There are various versions of the R-ladder, such as one with six steps, one with nine steps, and the butterfly model by the Ellen MacArthur Foundation. At Seenons, we, like the butterfly model, distinguish between organic and technical materials. That is why we have divided the R-ladder into two versions:

- A general R-ladder for technical waste streams.

- A specific R-ladder for organic waste streams, such as food scraps and green waste.

Measurability: How do we make the R-ladder practical?

Why do we split the R-ladder?

By splitting the R-ladder, we can address the unique characteristics of different types of waste streams. What works for technical materials, such as repairing electronics, does not apply to organic waste like food scraps. Organic waste streams require specific strategies, such as composting or fermentation, which are irrelevant for technical materials.

The general R-ladder is based on the model from PBL (2019) and the Ladder of Lansink, focusing on technical waste streams. This includes reusing packaging, recycling metals, or refurbishing office furniture. The organic R-ladder is inspired by the Ladder of Moerman and the PBL report (2019), focusing on organic waste streams such as food scraps, orange peels, and coffee grounds. This split makes the R-ladder more concrete and applicable for organisations across diverse sectors.

Combined steps

To make the R-ladder more practical and measurable, we have combined certain steps. This was done for several reasons:

- Refuse, Rethink en Reduce: These steps have been consolidated into “Reduce” because it is challenging to quantitatively measure the impact of each step individually. While overall waste reduction is measurable, determining which specific strategy led to the reduction is often difficult.

In the general model for technical waste streams, we have also combined the following steps:

- Repair en Refurbish: These steps have been merged because, in practice, the distinction is often unclear. Both strategies focus on extending the lifespan of products through repairs or by replacing components.

- Remanufacture en Repurpose: These steps have been combined because both involve reusing components, either in their original function (remanufacture) or in a new application (repurpose).

By combining these steps, the R-ladder becomes easier to measure while preserving its core principles.

Additional steps

We have also added steps that are not typically included in the R-ladder, such as “incineration without energy recovery” and “landfilling”. These steps are derived from the Ladder of Lansink and provide a comprehensive overview of how all processing methods relate to each other. This makes it easier to identify areas for improvement and opportunities for more sustainable practices.

Download hier (gratis) onze ‘Road to Circularity’ in PDF:

💡 Want to learn how to apply these strategies to prevent and reduce waste in your organisation? Find practical tips in our Knowledge Center 🎓